Engineering & Tooling for Plastics

December 10, 2022 2023-06-08 15:36Engineering & Tooling for Plastics

Engineering &

Tooling for plastics

Engineering & Tooling for plastics

Success

Time is money, now more than ever, and we're here to help

Challenging projects are our playground

Projects that are technically, managerially and/or time extreme are where TIBO becomes your most precious asset. TIBO’s entire strategy and business model is structured to address two key aspects for its customer:

- Time is of the essence

- Investing in the enginnering and solution from the start is an investment that pays off

This is the solution

The sooner we team up, the bigger is your gain

For one key project up to complete programs

The markets we shine in

The applications we master

Pushing the limits, breaking the paradigms. We love to work with most complex and innovative tooling and molding process techonologies. 2K, 3K, Pick & Place overmolding, Foaming, high polish, gas assist, metal or plastic insert, foil, cable overmolding, name it, we master it, we push the limits, but never promise something we can’t deliver.

OEM who benefit from TIBO

Our customer's best kept secret

From ideation to fulfillment

From

ideation

Our offer

We "walk the talk" with expertise and creativity from the start to the finish line

See for yourself our key process right below

Product Development

TIBO's Process

Shape & Forms

From Class A surfaces to technical challenges, our precise, creative and passionate minds provide solutions that overcome our customer's challenging design and tricky requests.Fit & Function

Across all of our product and plastic tooling development projects, the WOW that we deliver to our customers every time is rooted in the synergy of our values effectively combined with our skilled teams, agiled process and strategic manufacturing network capability.

Our dynamic attitude and constant desire to go the extra mile fuels all our projects.

Design for Tooling Manufacturing, Molding & Assembly

By continuously incorporating our mold and process expertise into our product design process, we maximize your gains in quality and profitability.

This is also a key element to speed up your development time process.

Shape & Forms

Fit & Function

Design for Tooling Manufacturing, Molding & Assembly

By continuously incorporating our mold and process expertise into our product design process, we maximize your gains in quality and profitability.

This is also a key element to speed up your development time process.

Tooling Development

TIBO's Process

Product Design Validation & Optimization for Manufacturing (Quality & Cost)

- Everything goes through our center of expertise in Canada;

- Top of the industry detailed DFM & mold flow analysis performed on 100% of our projects;

- Innovative, patented warping compensation solution that impresses our customers;

- Structured, detailed and timely project management starts here and never lets go until project delivery and your complete satisfaction.

AVG. TIMEFRAME : 2 -4 WEEKS

Mold Design for Manufacturing

- Everything goes through our center of expertise in Canada;

- Expertise, expertise, expertise... We have plenty of it;

- Around the clock optimized design output force;

- Challenges that are "impossible" or "too risky" for others; we love it, we thrive on it;

- Your involvement and expertise is more than welcome,

- But in all cases, it is the ownership of our solution that leads the way.

Mold Manufacturing & Manufacturing Quality Control

- Most of our manufacturing is done by our network of long-term Asian partners, with "unlimited capacity";

- Machining and finishing that meet and exceed industry standards;

- 100% pre-approved TIBO processes, steels, components, surface treatments and finishes;

- 100% TIBO technical resources on site to monitor and follow on everything;

- Canadian mold manufacturing capacity also available for some specific North American requirements.

Mold Trials, Samplings, Mold Optimization and Surface Finishes

- 100% on-site TIBO technical resources to monitor, support and excel;

- Detailed mold trial reports with real status and real solutions;

- Trials samples and reports analyzed and forwarded to our center of expertise in Canada;

- Internal preliminary mold validation process (prior to the second mold trial).

Mold Trials, Samplings, Mold Optimization and Surface Finishes

- Final mold setup to match your equipment and press;

- 4H "pre-production" mold trial to ensure performance;

- A proven key phase that provides ready-to-run tools for your SOP;

- Vacuum sealed and robust tool packaging for your peace of mind.

AVG. TIMEFRAME : 1.5 - 2 WEEKS

Mold shipping (air & sea)

From Asia to wherever you are, with our long-time shipping partner, we shine with exceptional on-time and cost-saving performance that outperforms the competitionMold start-up and process optimization at the customer’s site

- Over 35 years of experience resources at the customer's site to optimize mold performance on your press;

- Our expert moldmaking resources are available for the final adjustments that require your production environment;

- In short, from ideation to fulfillment, delivered at last.

Project Postmortem and Customer’s Satisfaction Fulfillment Validation

- Industry-leading tooling guarantee and solution ownership;

- We strive to deliver, we walk the talk and do it, and if, exceptionally, we don't, we fix it.

- We turn everything we learn in our projects into opportunities for future projects.

Innovation, Other equipments, Mold Modification, Repair and Maintenance Services

- An innovative spirit that strives to apply the latest technologies, to develop new solutions;

- Checking fixture and other peripherical equipments;

- A dedicated team to provide the complete "after sales" solution;

- Resources based in Mexico and Canada to provide rapid on-site support to our customers;

- For new tooling, engineering and project management is provided by our center of expertise in Canada.

- Manufacturing is done through our strategically located partners.

Product Design Validation & Optimization for Manufacturing (Quality & Cost)

- Everything goes through our center of expertise in Canada;

- Top of the industry detailed DFM & mold flow analysis performed on 100% of our projects;

- Innovative, patented warping compensation solution that impresses our customers;

- Structured, detailed and timely project management starts here and never lets go until project delivery and your complete satisfaction.

Mold Design for Manufacturing

(Quality & Cost)

- Everything goes through our center of expertise in Canada;

- Expertise, expertise, expertise… We have plenty of it;

- Around the clock optimized design output force;

- Challenges that are “impossible” or “too risky” for others; we love it, we thrive on it;

- Your involvement and expertise is more than welcome,

- But in all cases, it is the ownership of our solution that leads the way.

Mold Manufacturing & Manufacturing Quality Control

- Most of our manufacturing is done by our network of long-term Asian partners, with “unlimited capacity”;

- Machining and finishing that meet and exceed industry standards;

- 100% pre-approved TIBO processes, steels, components, surface treatments and finishes;

- 100% TIBO technical resources on site to monitor and follow on everything;

- Canadian mold manufacturing capacity also available for some specific North American requirements.

Mold Trials, Samplings, Mold Optimization and Surface Finishes

- 100% on-site TIBO technical resources to monitor, support and excel;

- Detailed mold trial reports with real status and real solutions;

- Trials samples and reports analyzed and forwarded to our center of expertise in Canada;

- Internal preliminary mold validation process (prior to the second mold trial).

Final Mold Validation, Run at rate and Mold Packaging

- Final mold setup to match your equipment and press;

- 4H “pre-production” mold trial to ensure performance;

- A proven key phase that provides ready-to-run tools for your SOP;

- Vacuum sealed and robust tool packaging for your peace of mind.

Mold shipping

(air & sea)

Mold start-up and process optimization at the customer’s site

- Over 35 years of experience resources at the customer’s site to optimize mold performance on your press;

- Our expert moldmaking resources are available for the final adjustments that require your production environment;

- In short, from ideation to fulfillment, delivered at last.

Project Postmortem and Customer’s Satisfaction Fulfillment Validation

- Industry-leading tooling guarantee and solution ownership;

- We strive to deliver, we walk the talk and do it, and if, exceptionally, we don’t, we fix it;

- We turn everything we learn in our projects into opportunities for future projects.

Innovation, Other equipments, Mold Modification, Repair and Maintenance Services

- An innovative spirit that strives to apply the latest technologies, to develop new solutions;

- Checking fixture and other peripherical equipments;

- A dedicated team to provide the complete “after sales” solution;

- Resources based in Mexico and Canada to provide rapid on-site support to our customers;

- For new tooling, engineering and project management is provided by our center of expertise in Canada;

- Manufacturing is done through our strategically located partners.

Let us optimize your project’s performance with our key process

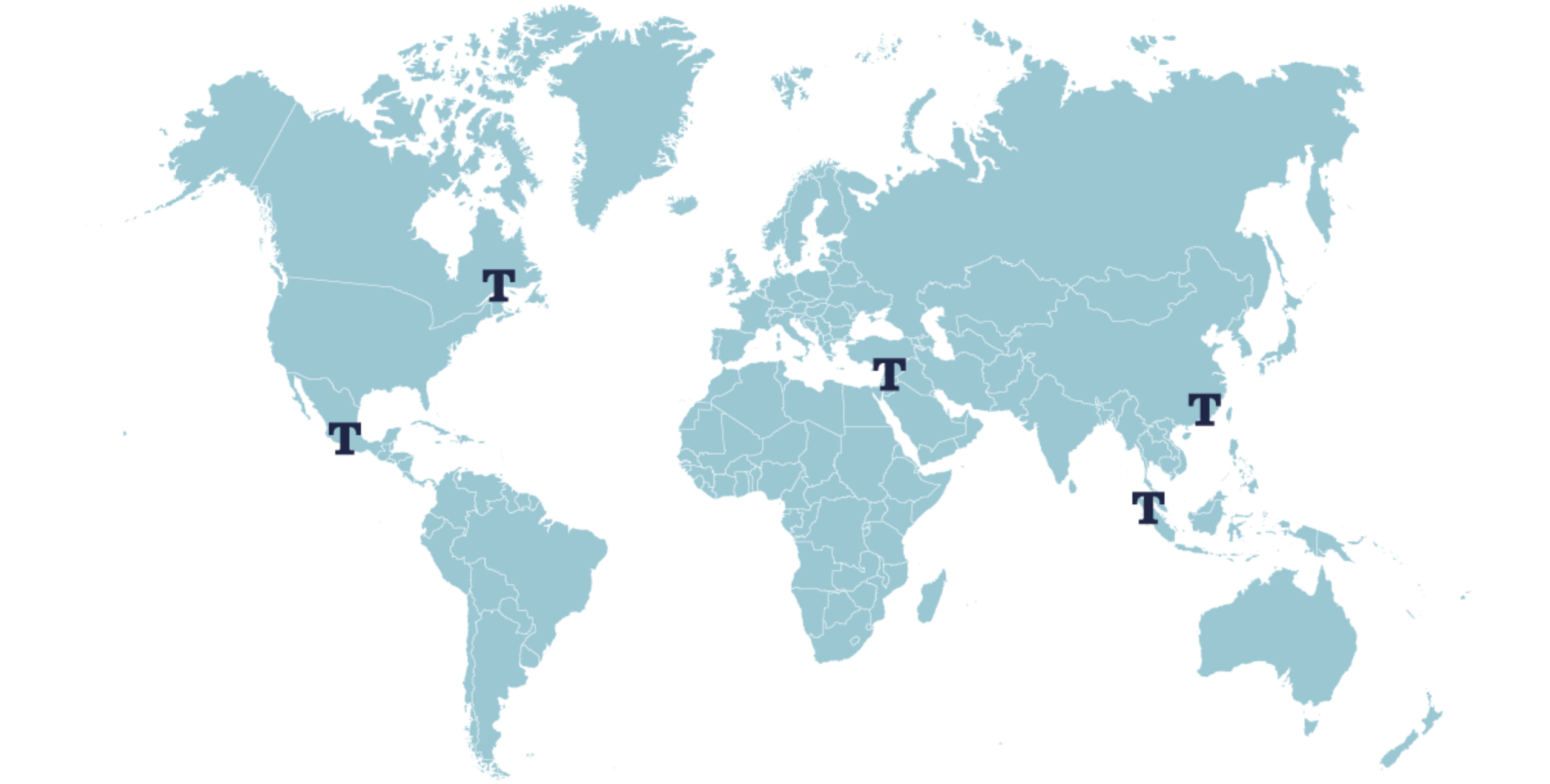

Lévis, Canada

Company headquarters and corporate expertise channeling center

- Product design

- Plastics injection and compression mold design

- Project management

- After sales Canada services unit (mold repair, maintenance and modification)

- Administration and top management

Zhejiang & Dongguan, China

TIBO engineering employees 100% on site, controlling, testing and validating EVERYTHING

- Over 425,000 square feet of production manufacturing capacity spread across our four tooling manufacturing partners

- Up to 300 tools successfully shipped every year

- Tools of all sizes and complexities

- Almost unlimited capacity since 2011

Juarez & Puebla, Mexico

After sales TIBO Mexico units- Network of strategic manufacturing partners for mold repair, maintenance and modification

- Serving our key automotive and powersport markets since 2013

Beirut, Lebanon

TIBO's engineering quoting support team. The key of our detailed proposal since 2009.Kuala Lumpur, Malaysia

TIBO product development CAD design support team

Our Tooling Capacity

Over the past decade, our value offer has clearly evolved with our integration skills. First, we have integrated our engineering, expertise and values into everything we do and deliver.

Second, we have integrated the manufacturing capabilities and skills of our long-term partners to produce tools that set us apart.

With our global network, we have the perfect combination of capabilities, capacity, quality and competitiveness to complement our offering.

Over 425,000 square feet of factory space combined with TIBO’s expertise is at your service.

- Product design

- Plastics injection and compression mold design

- Project management

- After sales Canada services unit (mold repair, maintenance and modification)

- Administration and top management

- Over 425,000 square feet of production manufacturing capacity spread across our four tooling manufacturing partners

- Up to 300 tools successfully shipped every year

- Tools of all sizes and complexities

- Almost unlimited capacity since 2011

- Network of strategic manufacturing partners for mold repair, maintenance and modification

- Serving our key automotive and powersport markets since 2013

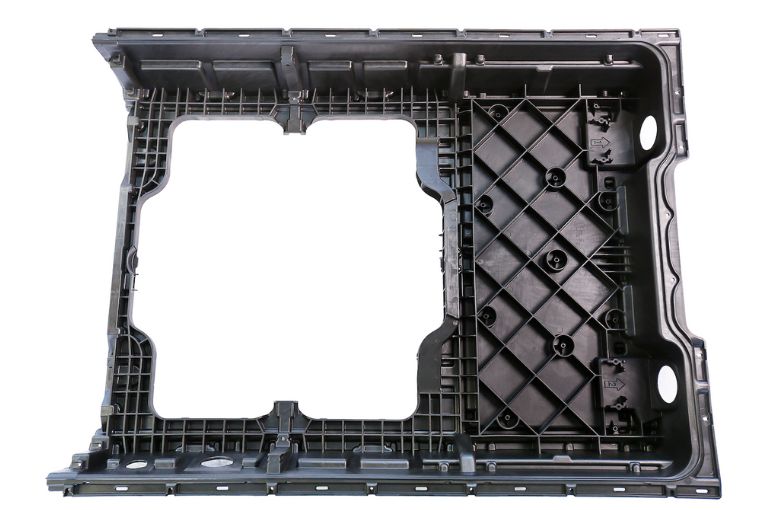

Some of TIBO's WOW delivered

Why

Why TIBO

The multiple reasons to team up with us

Creativity & Passion

Unity & Partnership

Agility & Resilience

Dynamism & Pride

testimonials

The ultimate reward we are aiming for

To summarize, our most priceless reward and our constant objective are our customers who confirm year after year that they could not imagine the success of their latest project without TIBO’s performance.

Ignacio Osorio

A&P Solutions, MexicoJesús Rascón C.

Unicar Plastics, MexicoFrédéric Labbé

Delastek, MexicoJames Daugherty

Jones Plastics & EngineeringSylvain Simard

EXO-SLet us help you overcome challenges and achieve your goals

Engineering & tooling for plastics in accordance with ISO 9001-2015

Success Stories

Powersport | Boat Rear Deck

Automotive | Lucid Frunk

Career

Level up your skills